Engineering capabilities at Holloway

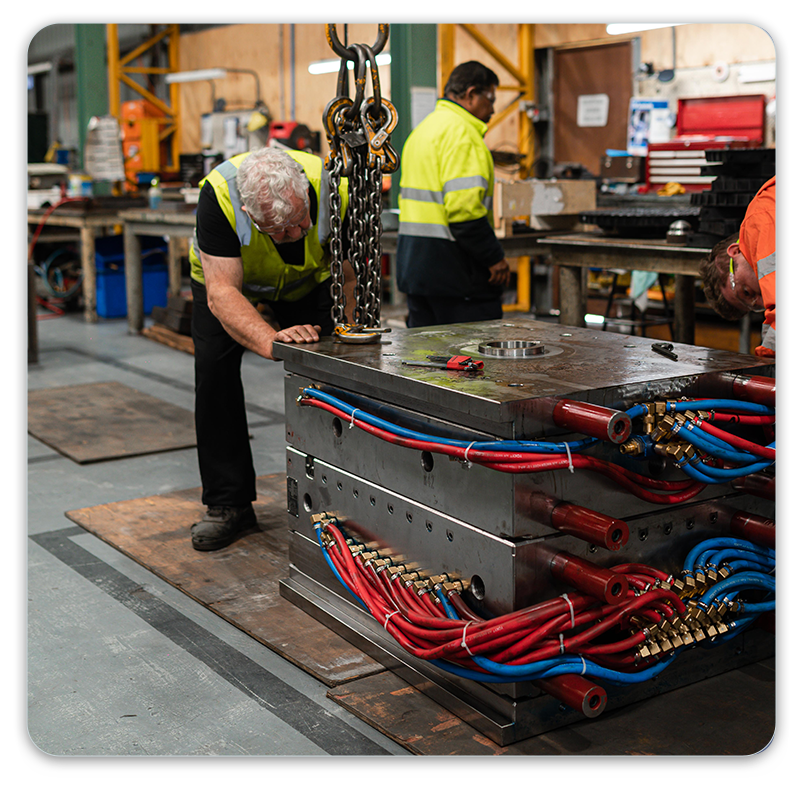

At Holloway Emerge, our specialised teams excel in various areas of design and manufacturing, including injection moulds, die-casting moulds, CNC machining for large components, press moulds, prototypes, and tooling maintenance. With our advanced Pro E Cad/Cam system, we possess the capability to manage your tooling or injection mould design project comprehensively, from initial stages to the final outcome.

Get in Touch with Us

Our teams specialise the design and manufacture of injection moulds, die-casting moulds, CNC machining or large components, press moulds, prototypes and tooling maintenance.

With our Pro E Cad/Cam system, we can handle your tooling or injection mould design project from start to finish. Our tradesmen range from toolmakers with decades of experience to qualified machinists, specialising in CAD/CAM, from basic production to precision hand finishing work.

With access to Global Manufacturing Facilities, we can cater for any tooling requirements quickly and efficiently.

Some of our equipment includes: Wire cutting, Spark Erosion, CNC machining up to 4 axis, CNC Lathes, Manual Milling, Manual Lathes, CMM and Grinding. We can supply documentation for 1st article inspection to 100% inspection with Certificates of Conformance including mill certificates for material.

We have a wealth of experience CNC machining of precision components and we can assist you with every aspect of your project from design to manufacturing. Using the latest technology in machinery and software, our Sydney team are able to produce quality products at a competitive price within a short lead time. We can machine complex products straight from your electronic model, or alternatively, we can create these models for you and feed this information into any one of our CNC machines.

We have established a very close working relationship with several tool rooms in Asia. We understand that dealing with overseas suppliers can be stressful and uncertain. We offer you a complete Project Management package with the resources to efficiently handle your custom tooling or injection mould project from start to finish, including: component design, prototyping, mould design, manufacture of tooling, personal overseeing of the project, supervision of trials including overseas visits when required.

You will deal directly with our friendly staff based in our Sydney office, while all overseas communications are taken care of in a timely and professional manner. Samples are provided for approval prior to shipment from the supplier to ensure quality satisfaction.

Get In TouchLet's work together Our specialist teams are here to help.

For a quick response, fill out as much as you can or alternatively call the team on 02 9603 2088.